Design of such a style and design House really helps to discover the exceptional circumstances for the lyo process, the boundaries of failure, and the bounds (ranges) for validation and the limits for process Regulate to get a offered vial configuration, machines, and producing ecosystem. Moreover, it can be used to forecast the influence of versions in process ailments, to the process performance, and product high-quality characteristics which will help in comprehension the effects of excursions/deviations through manufacturing.

Our user-pleasant configurator simplifies the process, making certain your great fume hood is just a couple clicks absent.

The pre-freezing in the compound to generally be dried is the first step inside the lyophilization process. Pre-freezing will be the process of lowering the temperature of a material considerably below its freezing stage to be able to assure the event of small, homogeneous ice crystals.

This information describes a procedure to facilitate scale-up for the key drying phase of lyophilization working with a mix of empirical tests and numerical modeling. Freeze dry microscopy is made use of to determine the temperature at which lyophile collapse takes place. A laboratory scale freeze-dryer equipped with manometric temperature measurement is utilized to characterize the formulation-dependent mass transfer resistance of the lyophile and establish an optimized laboratory scale Major drying stage in the freeze-drying cycle. Characterization of warmth transfer at equally lab and pilot scales has long been ascertained from details collected for the duration of a lyophilization cycle involving surrogate content. Using the empirically derived mass transfer resistance and warmth transfer facts, a semi-empirical computational heat and mass transfer design at first formulated by Mascarenhas et al.

Richard Altmann, a German histologist, designed an important advance in 1906 when he efficiently freeze-dried bacteria for preservation and afterwards revived them. This experiment set the framework for the process’s long term evolution.

The process structure experiments will not need to be carried out underneath very good production exercise (GMP) disorders but needs to be based on scientifically audio methods and may be adequately documented and verified (seven).

The entire process is carried out at reduced temperature and tension by making use of vacuum, that's why is suited to drying of thermolabile compounds. The focus gradient of water vapour concerning the drying front and condenser will be the driving pressure for removing of water all through lyophilization.

If you desire to additional information with regards to this collaborative effectiveness validation among company, industrial hygiene consulting business, and customer; make sure you down load a duplicate from the presentation at the subsequent hyperlink:

The resistance to warmth transfer originates through the products by which the heat must journey to get to the item. These website resources contain the fluid flowing through the shelves, the stainless steel cabinets, the main packaging in connection with the cabinets, and the air Area between the bottom of the key packaging along with the shelves. The warmth transfer coefficient of the primary container (Kv) differs from container to container and it is dependent on the chamber pressure. The heat transfer coefficient represents the ratio of the heat move from cabinets for the product or service within a supplied vial, the outer cross-sectional region of your vial, and also the temperature difference between the shelf surface area as well as the products at the bottom in the vial (9).

The typical plans for implementing CIN are to lessen variability and to scale back lyophilization processing time. The reduction in processing time might be extra sizeable for some formulations than for Other individuals. By way of example, amorphous formulations with small significant product temperatures generally have to have conservative processing circumstances to prevent collapse for the duration of Principal drying.

The shelf heaters manage the mandatory temperature ranges all over the numerous drying cycles to supply an productive and successful lyophilization process.

The solution demonstrates the connection concerning the process inputs; it relies on first ideas and offers an intensive scientific idea of process and products. The lyophilization process modeling and scale-up are presented displaying the impression of facility, equipment, and vial heat transfer coefficient. The case studies demonstrating the impact of batch sizes, fill volume, and dose power to show the necessity of modeling plus the outcome of managed nucleation on product resistance are discussed.

Acquire these actions to put in place your new FreeZone Freeze Dryer Console. The online video consists of Guidelines for putting in a multi-port manifold or possibly a chamber with valve ports.

Lyophilization is actually a multi-phase treatment that necessitates the get more info use of specialised products and professional personnel. The course of action is technically sophisticated and sensitive to variants as it comprises freezing, sublimation, and vacuum functions.

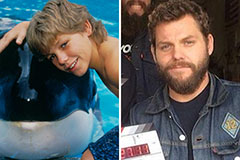

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!